“Following a devastating fire, Dayspring’s ability to pull resources from all over the state within hours was incredible. They had over 50 workers onsite within 2-3 hours! We would never have been able to have our students back in school within 2 days were it not for the quick response and the quality of work provided by them. Their quality of work was excellent!”

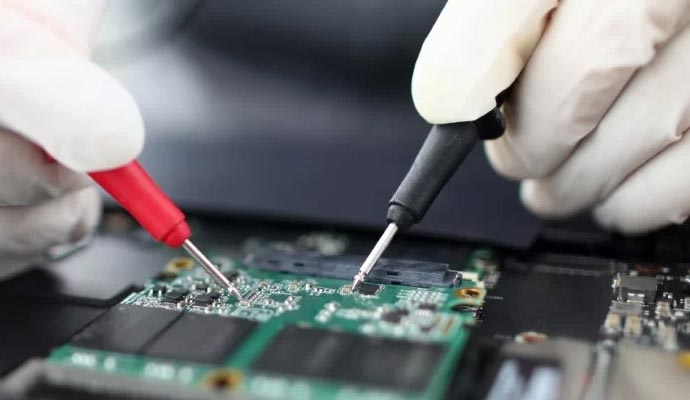

Pre-evaluated electronics are first taken to the Disassembly Station, where they can be more closely inspected and a course of action determined. They are then disassembled and prepped for cleaning and decontamination.